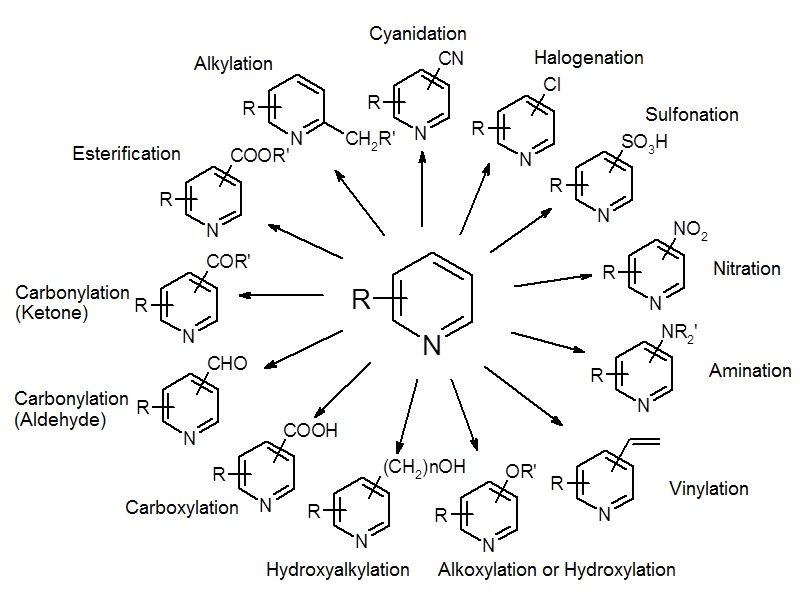

We utilize the fixed-bed gas phase reaction technology we have developed over many long years in order to synthesize a variety of pyridines. In addition, this technology can be combined with fine organic syntheses using liquid-phase reaction technologies to meet a range of clients’ needs for pyridines, pyrazines, piperazines, and other materials.

In recent years, we have deployed a range of technology for manufacture of materials at extreme low temperature, as well as dry and oxygen-free conditions, allowing for the support of the more complex processes of organic synthesis.

Liquid-phase multi-purpose manufacturing facilities

This page can be viewed by scrolling.

| Equipment | Specifications | |

|---|---|---|

| Liquid-phase reactor | Capacity | 1-10m3 |

| Material | GL, SUS, Hastelloy | |

| Supported pressure | ~0.98MPa(G) | |

| Supported temperature | -60-180℃ | |

| Distillation equipment | Capacity | 1.2-20m3 |

| Material | SUS, SS | |

| Theoretical plates | 10-16 stages | |

| Maximum usage temperature | 300℃ | |

| Centrifugal separator | Capacity | 32-40 inch |

| Material | SUS,Aflon | |

| Dryer | Capacity | 1-3m3 |

| Material | Hastelloy, GL, SUS | |

| Filtration equipment | Capacity | 0.2-3.0m3 |

| Material | GL, SUS | |

| Misc. | Thin film distillation: SUS 3.1m2 | |

| Filtration drying: SUS 0.6m2, 1m2 | ||

For product inquiries and to download a catalog,

please click the button below.