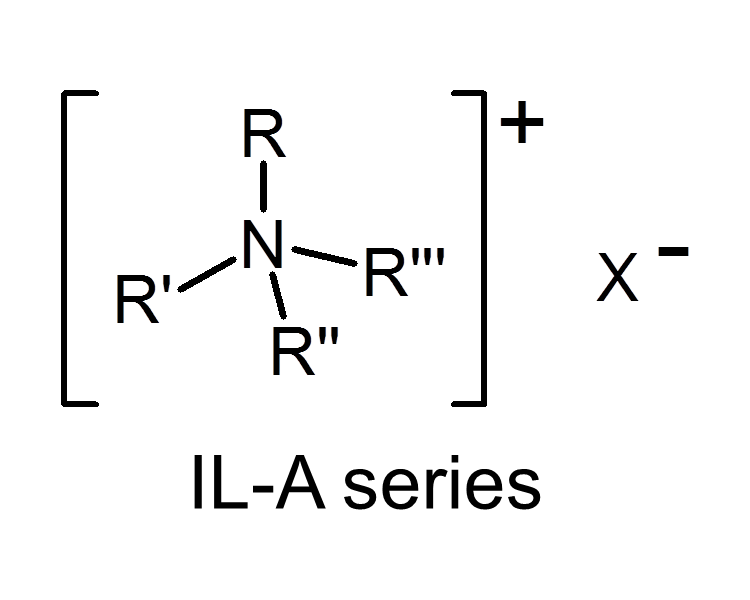

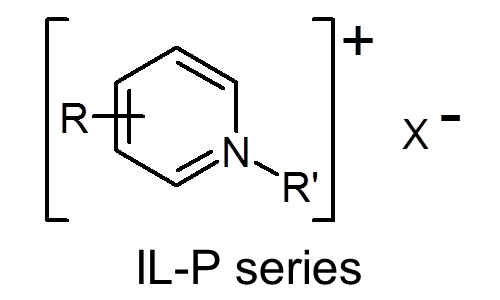

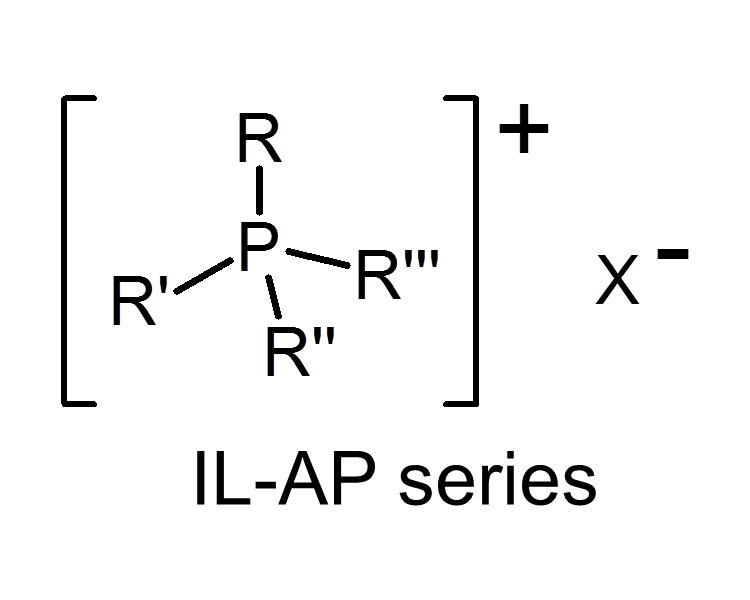

Our relevant product

IL-A series, IL-P series, IL-AP series

Structures

Characteristics

- Resin transparency is maintained by optimizing the structure of an ionic liquid and adjusting its compatibility to the target resin. Excellent antistatic performance is exhibited by the addition of a small amount of ionic liquid.

- As antistatic performance is exhibited by the ion-conductive property of the ionic liquid itself, it is insusceptible to environmental (humidity) conditions.

- Ionic liquids show excellent flameproofness and can be kneaded into resins such as polycarbonate.

Information on typical products

This page can be viewed by scrolling.

| Product | Status of registration of chemical substances in various countries | Poisonous substances laws | Fire services laws |

|---|---|---|---|

| IL-A2 | Registered (Japan, Korea, Taiwan) |

Not applicable | Designated flammable goods Flammable liquids |

| IL-AP3 | Registered (Japan, Taiwan) |

Not applicable | Designated flammable goods Flammable liquids |

| IL-P14 | Registered (Japan, Korea, Taiwan) |

Not applicable | Designated flammable goods Flammable liquids |

Physical properties

This page can be viewed by scrolling.

| Product name | Appearance | Melting point (℃) |

Decomposition temperature (℃)* |

Viscosity (mPa•s) |

|---|---|---|---|---|

| IL-A2 | Colorless to pale yellow clear liquid | <0 | 347 | 635(25℃) |

| IL-AP3 | Colorless to pale yellow clear liquid Or white to pale yellow solid | 17 | 369 | 338(25℃) |

| IL-P14 | Colorless to pale yellow clear liquid Or white to pale yellow solid | 12 | 369 | 85(25℃) |

*Decomposition temperature at which a 5% weight loss was observed by TG-DTA analysis

Technical information

Examples of application to UV hard coating agents

This page can be viewed by scrolling.

| Product name | Amount (%) added | Surface resistivity (Ω/sq)* |

|---|---|---|

| Blank | 0 | >1×1014 |

| IL-A2 | 1 | 1×1011 |

| IL-AP3 | 1 | 2×1011 |

●Film forming conditions

Base material:TAC film

Coating agent:Monomer: multifunctional acrylate Solvent: 2-propanol

Coating:Bar coater #5, drying at 60℃ (20 minutes)

Hardening:High-pressure mercury vapor lamp, integral light intensity: 400±10 mJ/cm2

*Measurement condition of surface resistivity

Applied voltage:500V

Measurement environment:25℃±2℃、45±5%RH

Surface resistivity meter:Hiresta UP (MCP-HT450), Mitsubishi Chemical

Examples of application to polycarbonates

This page can be viewed by scrolling.

| Product name | Amount (weight %) added | Surface resistivity (Ω/sq) |

|---|---|---|

| Blank | 0 | >1×1014 |

| IL-AP3 | 0.5 | 6×1012 |

| 1 | 1×1011 |

●Molding conditions

Base material:Polycarbonate

Molding machine:Injection molding machine

Molding temperature:320℃、2min

Examples of usage

- Giving antistatic property to UV hard coating agents

- Giving antistatic property to adhesives

- Giving antistatic property to paints for building materials

- Giving antistatic property for polycarbonate kneading

* The stated physical properties and technical information are representative values measured by Koei Chemical. Performance and other specifications are not guaranteed.

For product inquiries and to download a catalog,

please click the button below.